Electro Deionization (EDI) Water Treatment System

At GWT, we specialize in advanced water treatment solutions like Electro Deionization (EDI) systems and Deionization (DI) plants. Electro Deionization (EDI) systems differ from traditional ion-exchange methods by offering a cost-effective, eco-friendly solution for producing ultra-pure water. EDI technology combines reverse osmosis and Electro Deionization to eliminate harmful ions and impurities, ensuring higher EDI quality water with minimal EDI cleaning. Ideal for industries like pharmaceuticals and power generation, our customizable EDI modules and DM plants deliver pure water globally, surpassing conventional Deionization (DI) systems in efficiency.

Why Choose EDI for Treatment Plants in the UAE?

The UAE faces unique challenges related to water scarcity and quality. EDI systems are increasingly being used in treatment plants in the UAE due to their ability to produce high-quality, ultra-pure water. With DM water plants across the globe adopting EDI technology, the UAE is also embracing this advanced solution to meet its water needs. GWT offers containerized DM systems and EDI units that help industries in the UAE maintain a reliable supply of purified water.

Electro Deionization (EDI) is a cutting-edge water purification technology that combines reverse osmosis (RO) and ion-exchange resins to remove dissolved ions from water. The EDI system uses an electrical current to remove the majority of water impurities, offering higher EDI quality and minimal need for infrequent EDI cleaning. Unlike traditional demineralisation processes, EDI delivers consistent high-purity water without relying on chemicals for regeneration.

How Does Our Electro Deionization Plant Work?

At GWT, our Electro Deionization (EDI) units use advanced EDI technology for ultra-pure water. Combining reverse osmosis with ion-selective membranes and an electric current, our system efficiently removes salts, organic compounds, and impurities without chemical regeneration.

Benefits of GWT Electro Deionization (EDI) System

Continuous Operation

Provides uninterrupted, high-quality water treatment with minimal downtime.

Low Maintenance

Requires infrequent EDI cleaning, reducing operational costs.

Eco-Friendly

No reliance on chemicals for regeneration, making it environmentally sustainable.

Energy-Efficient

EDI systems consume less energy compared to traditional DI systems.

Compact Design

Our EDI modules are compact and easy to integrate into existing infrastructure.

Difference Between Electro Deionization (EDI) & Electro Demineralization (EDM):

EDI uses an electric field to remove ions continuously without chemicals, offering higher purity and efficiency. EDM, however, relies on ion-exchange resins and requires chemical regeneration, making it less efficient and requiring more maintenance.

Major Industrial Applications of DM Plants

Demineralized water treatment plants are used in industries such as:

Boiler Feed Water

Cooling Tower Make-Up Water

Food Processing

Pharmaceutical Manufacturing

Textile Industry

Beverage and Soft Drink Production

Battery & Automobile Plants

Fertilizer Plants

Industry-Wide Water Treatment Solutions

DM plants are widely used across various industries such as power generation, pharmaceuticals, food processing, textiles, and automotive manufacturing. These plants provide high-purity water essential for processes like boiler feed, cooling systems, and product quality control in these sectors.

GWT Other Water Treatment Solutions

Sea Water Reverse Osmosis

Used for desalination to convert seawater into potable or industrial-grade water.

Brackish Water Reverse Osmosis

Ideal for purifying brackish water in areas with slightly saline water sources.

Electro Deionization & Demineralization

Applied in industries for producing ultra-pure water free from dissolved salts and ions.

FAQ

What is EDI in water treatment system?

EDI (Electro Deionization) is a water treatment process that removes ions from water using an electric field, ion-exchange resins, and selective membranes. It is used to produce ultra-pure water for industries like pharmaceuticals, power plants, and electronics.

What is the process of Electro Deionization?

The process involves water passing through ion-exchange resins and selective membranes while an electric current moves ions through these materials. This results in purified water with minimal contaminants and minerals, ideal for sensitive industrial applications.

What are the benefits of Electro Deionization?

Benefits of EDI include higher water purity, reduced operational costs (as it requires less cleaning and maintenance), environmentally friendly (no need for chemical regeneration), and continuous operation, providing a reliable supply of ultra-pure water.

What is the difference between Electro Deionization and deionization?

Electro Deionization (EDI) uses electricity to remove ions from water, offering continuous, chemical-free purification. Traditional deionization (DI) relies on ion-exchange resins and requires frequent regeneration, making EDI more efficient and cost-effective in the long run.

Our Partners

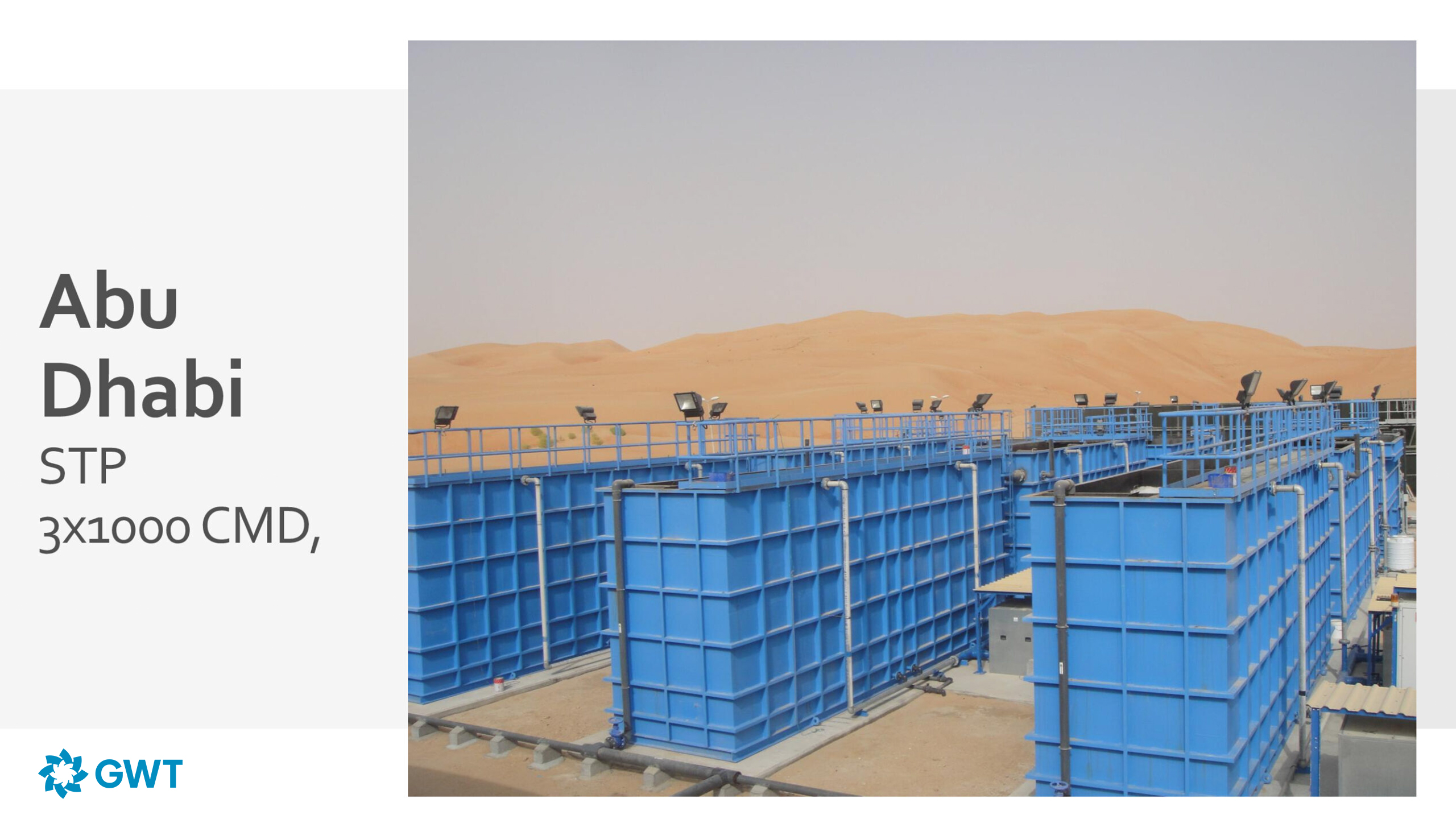

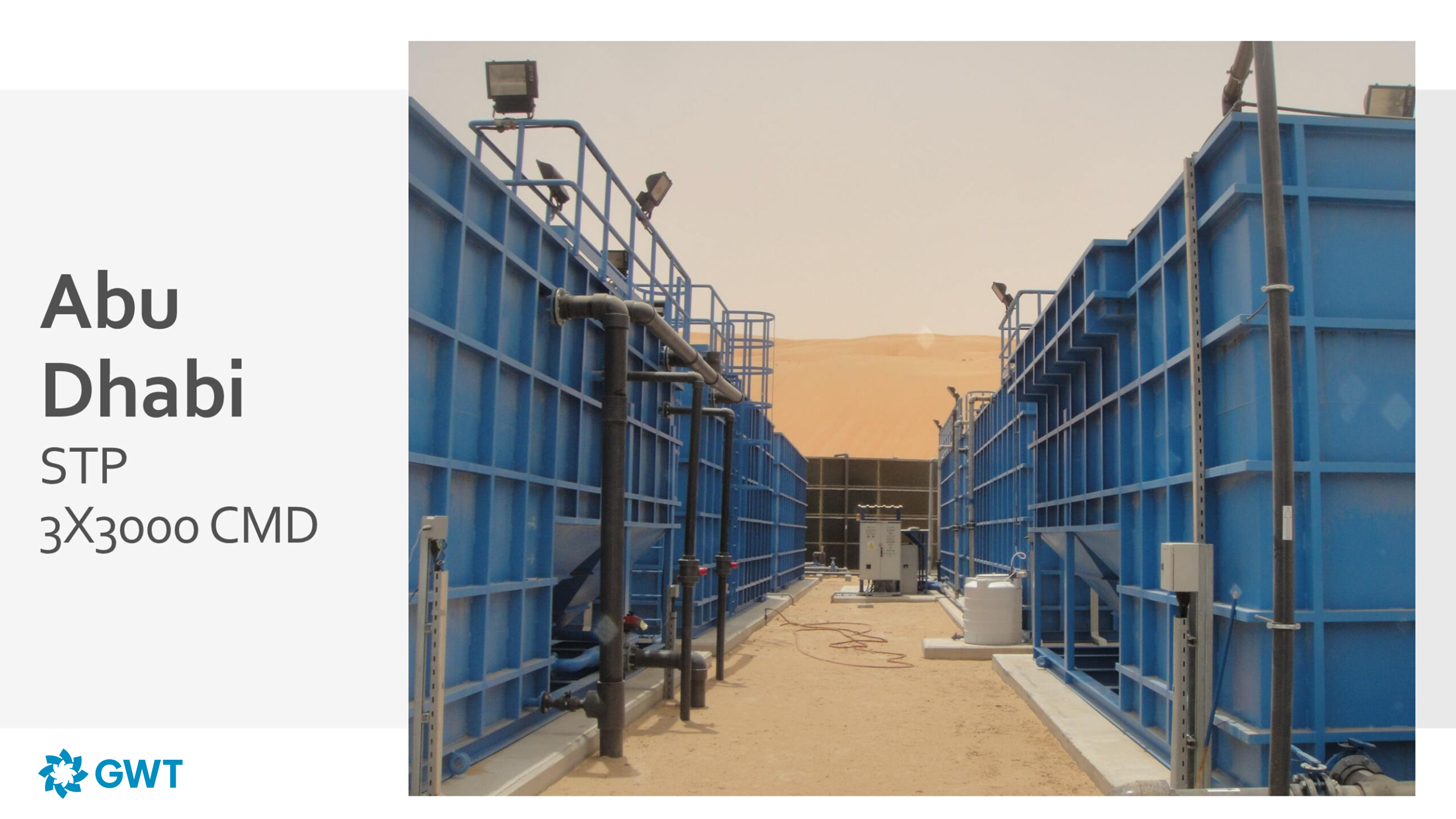

Projects